High-Efficiency Dust Collector System for Precious Metal Refineries

Problem:

In precious metal refineries, significant amounts of valuable material are lost as airborne dust during the refining process. These losses, often occurring in the form of ultra-fine particles, can accumulate quickly, leading to substantial financial setbacks.

Traditional dust collection methods, typically designed for more general applications, often fail to capture these fine dust particles efficiently. As a result, precious metals like gold, silver, platinum, and palladium that should be recovered from the process escape into the atmosphere or become trapped in waste systems, diminishing profitability and operational efficiency.

Additionally, the risks posed by airborne dust go beyond financial losses. This dust, especially when handling materials like precious metals, is not only hazardous to the environment but also presents serious health and safety concerns for workers.

Chronic exposure to these airborne particles can lead to respiratory issues and long-term health risks. Furthermore, refineries are subject to increasingly stringent environmental regulations. Failing to meet these standards can result in penalties, legal liabilities, and damage to a refinery’s reputation.

To address these challenges, a specialized, high-efficiency dust collection system designed for the unique demands of precious metal refining is essential. The right system can significantly reduce material loss, improve safety, and ensure regulatory compliance, all while increasing operational efficiency.

Solution:

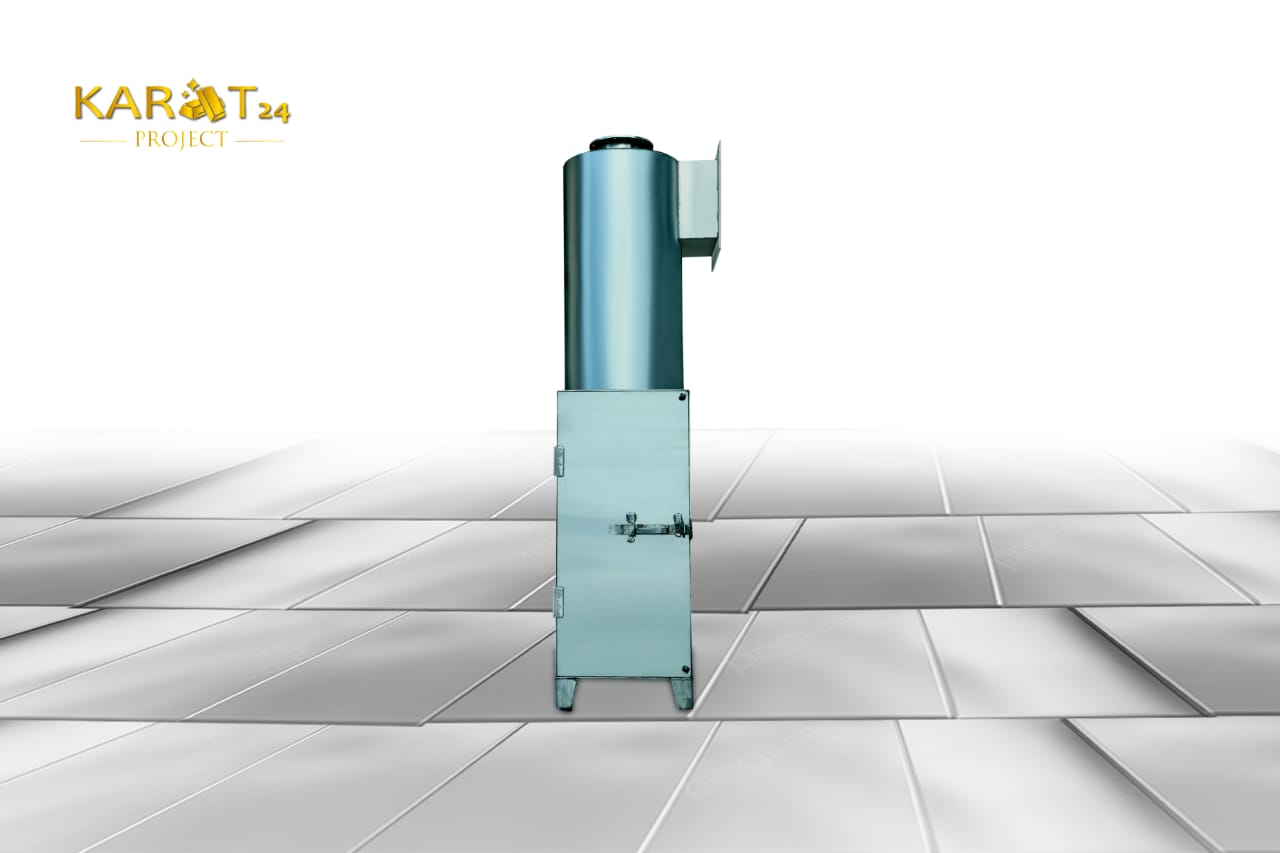

Our high-efficiency dust collector system is engineered specifically for the complex and demanding conditions of precious metal refineries. Unlike conventional systems, our dust collector system offers superior filtration, maximized material recovery, and optimal safety features, all while meeting environmental and regulatory standards.

With advanced technology and a robust design, this system is built to tackle the unique challenges posed by precious metal dust in a refinery setting.

Key Features & Benefits:

Superior Filtration:

- Advanced HEPA/ULPA Technology: Our dust collector system incorporates state-of-the-art HEPA (High-Efficiency Particulate Air) and ULPA (Ultra-Low Penetration Air) filters, capable of capturing particles as small as 0.3 microns with an efficiency rate of 99.99% or higher. This level of filtration is critical in a precious metal refinery, where even the smallest dust particles can contain significant amounts of precious metals. With this advanced filtration technology, virtually all dust generated during the refining process is captured, ensuring that no valuable material is lost to the atmosphere.

- Customizable Filter Configurations: Each refinery has unique dust composition, particle size, and volume. Our system offers customizable filter configurations tailored to meet these specific requirements. Whether dealing with fine particles, larger dust particles, or a combination of both, our dust collector system can be configured to optimize performance for each situation. This adaptability ensures that the dust collector system works at maximum efficiency, no matter the material being processed.

- Long-Term Filtration Efficiency: The durable nature of our filtration media means that they will remain highly effective over time, minimizing the need for frequent replacements. This reduces downtime and lowers the cost of ownership over the system’s lifecycle.

Robust and Durable Design:

- Built for Demanding Environments: Precious metal refineries are challenging environments where equipment must withstand high temperatures, aggressive chemicals, and abrasive dust. Our dust collector system is constructed from high-quality, corrosion-resistant materials designed to endure these harsh conditions. It is built to handle the extreme demands of continuous operation, ensuring that the system will continue to perform optimally for years to come.

- Continuous Operation: The design of our dust collector system allows for 24/7 operation, making it ideal for refineries that operate around the clock. Its rugged construction and high-quality components ensure reliable performance, even in high-volume environments, minimizing downtime and maximizing throughput.

- Long-Term Durability: The materials used in the construction of our system are selected for their resistance to corrosion and wear. This ensures the system remains operational for longer periods, reducing the frequency of maintenance and the costs associated with repairs or part replacements.

Efficient Dust Recovery:

- Integrated Recovery Systems: A key benefit of our dust collector system is its integrated dust recovery systems, designed to capture and store valuable dust particles that can be recovered for reprocessing. This system is equipped with a collection chamber that is strategically placed for maximum dust capture, allowing refineries to reclaim precious metals from their waste dust. This results in a significant reduction in material loss and ensures that refineries get the most value from their operations.

- Automated Dust Removal: Traditional dust removal methods often involve manual handling, which can be time-consuming and prone to errors, leading to potential losses. Our dust collector system features automated dust removal, reducing human intervention and enhancing efficiency. The automated system ensures that collected dust is efficiently processed, minimizing waste and further safeguarding valuable materials.

- Minimized Dust Handling: By automating the collection and recovery process, the system reduces the amount of handling required. This not only improves safety but also minimizes the chance of precious metals being lost due to mishandling or improper collection techniques.

Safety and Compliance:

- Enhanced Safety Features: Handling precious metal dust poses significant safety risks. Our dust collector system incorporates advanced safety features to mitigate these risks, including explosion-proof components, flame arrestors, and fail-safe mechanisms. These safety features are crucial for preventing accidents and ensuring that the system operates without incident, even under the challenging conditions of a refinery.

- Regulatory Compliance: Our dust collector system is fully compliant with the latest environmental regulations and safety standards, including those set by agencies such as OSHA (Occupational Safety and Health Administration) and the EPA (Environmental Protection Agency). It meets or exceeds all emission control standards, helping refineries avoid potential penalties and stay in good standing with regulatory bodies.

- Workplace Health and Safety: The system plays a pivotal role in creating a safer work environment by significantly reducing airborne dust levels. This not only protects the health of workers but also contributes to a more comfortable, productive workplace. With less airborne dust, employees are less likely to experience respiratory issues, and the risk of long-term health complications is minimized.

Optimized Performance:

- Consistent Airflow & Filtration: The performance of our dust collector system remains consistent even in high-demand situations. Designed to handle varying dust loads, the system ensures that airflow and filtration efficiency are maintained at optimal levels, preventing any drops in performance that could result in material loss or safety risks.

- Low Maintenance Requirements: Designed with ease of maintenance in mind, our dust collector system requires minimal upkeep. With self-cleaning filters and intuitive maintenance features, the system is easy to service, helping to minimize downtime and extend the life of the equipment. This ease of maintenance helps refineries avoid costly interruptions and keeps operations running smoothly.

- Energy-Efficient Operation: In addition to offering superior filtration, our system is designed to be energy-efficient. By reducing energy consumption without compromising performance, our dust collector system helps refineries reduce their carbon footprint and cut down on operating costs. This is especially important in today’s increasingly environmentally conscious world, where energy efficiency is a key factor in sustainable operations.

Value Proposition:

- Maximized Precious Metal Recovery: With our high-efficiency dust collector system, refineries can recover almost 100% of airborne precious metal dust, directly impacting profitability. The recovery of valuable materials from the dust ensures that no resources are wasted, and it enhances the overall financial performance of the refinery.

- Enhanced Workplace Safety: The reduction of airborne dust creates a safer, healthier work environment, protecting workers from respiratory issues and other health concerns related to exposure to harmful particles.

- Regulatory Compliance & Environmental Stewardship: Our system ensures full compliance with all environmental and safety regulations, helping refineries avoid fines and maintain their commitment to sustainable and responsible operations.

- Improved Operational Efficiency: The system streamlines dust collection and recovery processes, reducing the need for manual intervention, lowering material loss, and optimizing throughput. This leads to greater operational efficiency and reduced overall costs.

- Lower Total Cost of Ownership: By reducing material loss, lowering the frequency of filter replacements, and minimizing maintenance downtime, our dust collector system provides a lower total cost of ownership, resulting in better long-term value for refineries.

Do You Need this Product?

Consult with Our Experts: Schedule a consultation with our team of experts to evaluate your refinery’s specific needs and determine the optimal dust collector system configuration for your operation.

Explore Our Product Range: Discover our full range of high-efficiency dust collectors system, designed specifically for precious metal applications. We can provide tailored solutions to meet the unique requirements of your refinery.

Maximize Efficiency & Recovery: Contact us today to learn how our dust collector system can help improve your refinery’s operational efficiency, reduce material loss, and increase precious metal recovery.