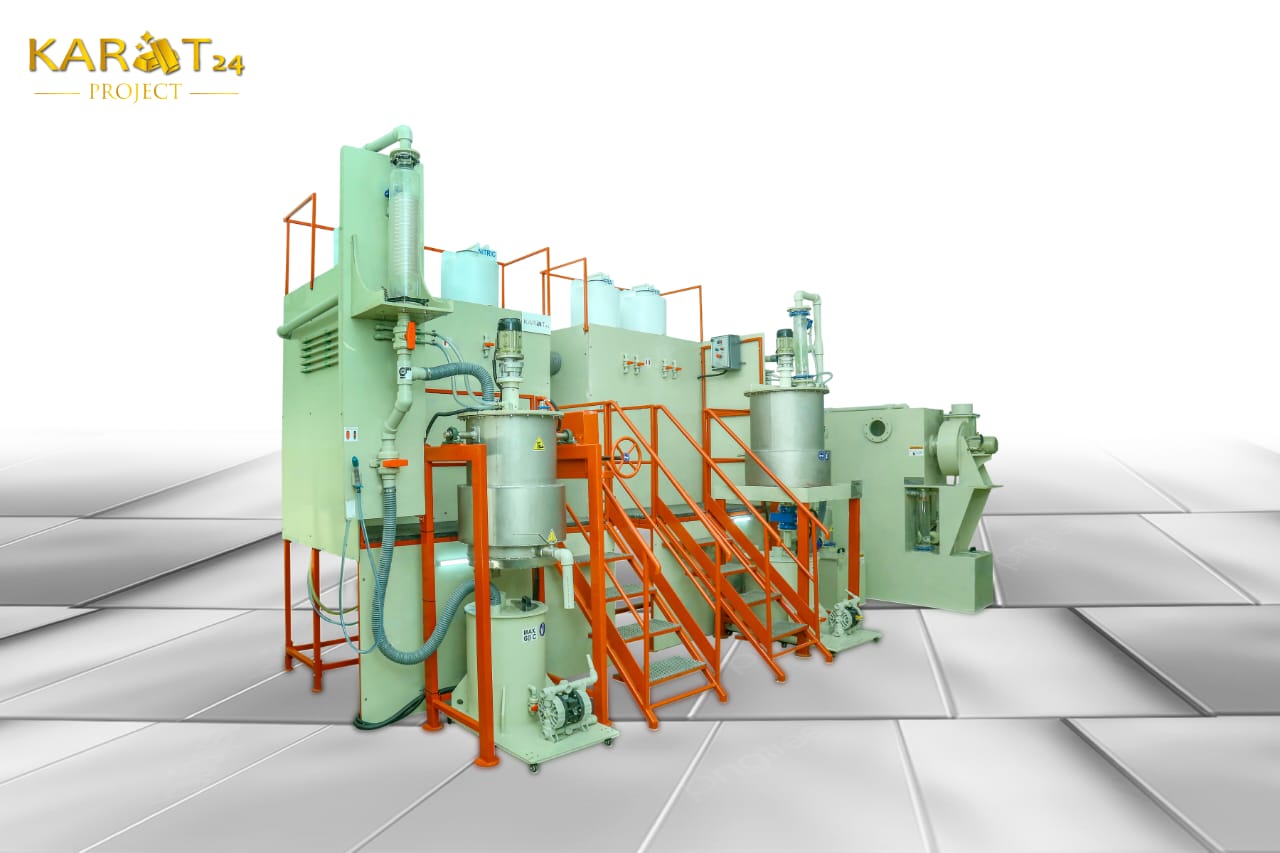

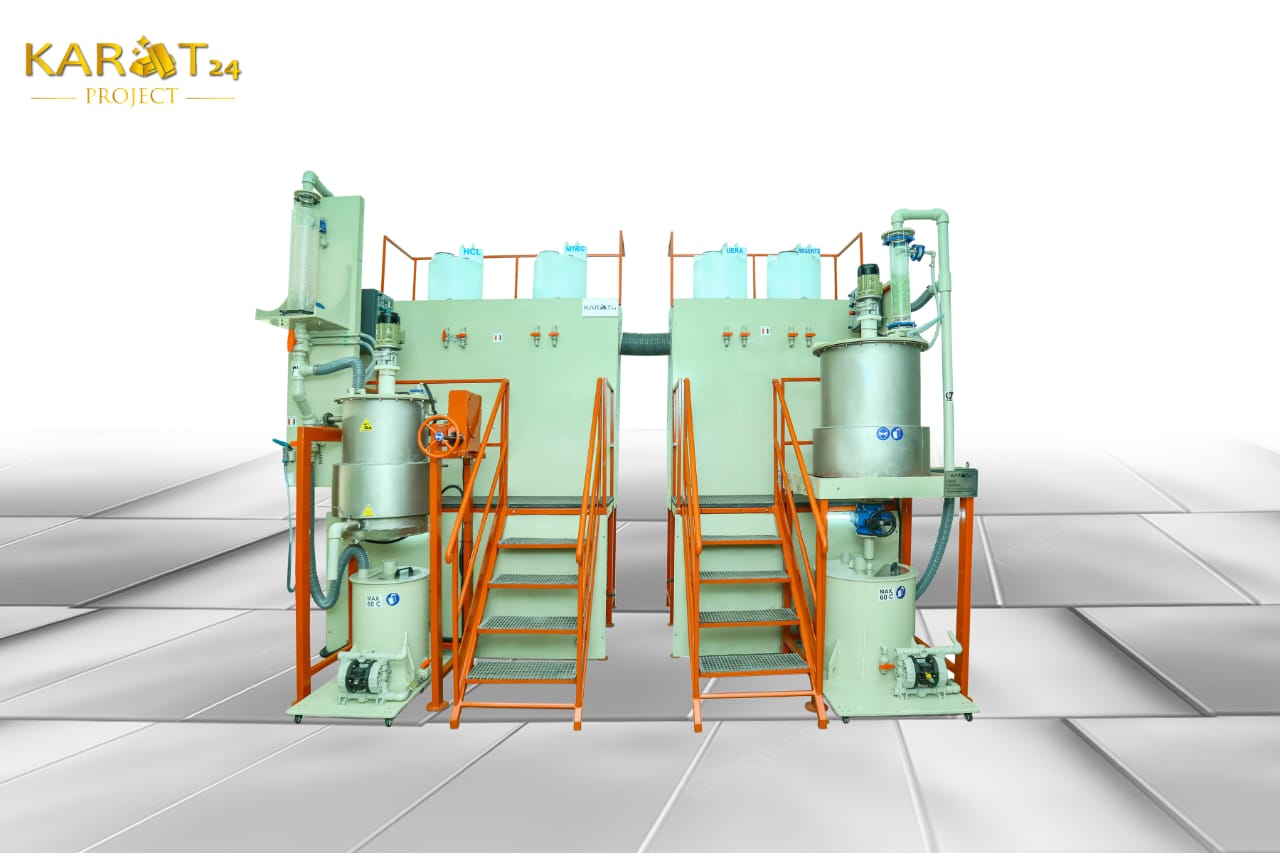

Precious Metal Refinery Machine

The Precious Metal Refining System is a cutting-edge solution meticulously designed for the precise and efficient refining of gold and other precious metals.

This system guarantees a superior, lustrous finish while ensuring optimal operational efficiency.

Renowned for its exceptional performance, low maintenance requirements, energy efficiency, and extended operational lifespan, the system is the perfect choice for businesses that prioritize quality and reliability.

Manufactured in our state-of-the-art, environmentally controlled facility, the refining system undergoes rigorous testing and quality control under the supervision of industry experts.

It is engineered to process a broad range of gold-bearing materials, including carat gold scrap, filings, polishing dust, and various precious metal alloys, making it a versatile asset for any precious metals operation.

Key Features and Specifications:

- Versatile Alloy Batch Capacity: Capable of handling batch sizes from 1 kg to 100 kg, providing flexibility to accommodate various production requirements, from small-scale operations to larger-scale refining processes.

- Efficient Working Cycle: Optimized for high throughput, the system is capable of processing up to three batches within a 24-hour cycle, ensuring maximum productivity with minimal downtime.

- Ultra-High Purity Attainment: The system consistently achieves gold purity levels ranging from 999.5 to 999.9 parts per thousand (99.95% to 99.99%), meeting the stringent requirements for high-value applications such as jewelry production, investment-grade gold, and other premium uses.

- Industrial-Grade Electrical Supply: Designed to seamlessly integrate with standard 3-phase electrical power systems, the system ensures stable, reliable operation across a wide variety of industrial environments.

- Advanced Refining Technology: Utilizing state-of-the-art refining processes, including electrolytic and chemical methods, the system effectively removes impurities and produces gold of the highest possible purity, guaranteeing outstanding results for every batch.

- Environmental Considerations: With a strong commitment to sustainability, the system is engineered to minimize its environmental impact, meeting the highest pollution control standards and promoting eco-friendly practices throughout the refining process.

- Durable Construction: Constructed with premium materials and components, this system is built to withstand the rigors of demanding industrial environments, ensuring exceptional durability and reliability over its long operational life.

- User-Friendly Interface: Featuring intuitive controls and an easy-to-navigate monitoring system, the Precious Metal Refining System simplifies operations, enabling operators to optimize the refining process with ease and precision.

- Safety Features: Equipped with a comprehensive range of safety mechanisms, the system is designed to protect operators, mitigate potential hazards, and ensure safe operation at all times.

- Customizable Solutions: To cater to a wide range of business needs, the system offers customizable options, allowing customers to tailor it to their specific production requirements and workflow preferences.

Benefits:

- Enhanced Gold Quality: Produces gold with exceptional purity and a flawless finish, maximizing its value for both commercial and investment purposes.

- Increased Productivity: With a highly efficient working cycle, the system boosts processing capacity, ensuring faster turnaround times and higher volumes of processed material.

- Reduced Operational Costs: The system is designed to reduce maintenance needs and minimize energy consumption, resulting in lower overall operational expenses.

- Consistent Performance: Offers reliable, repeatable results, ensuring that each refining cycle meets the same high standards of quality and purity, batch after batch.

- Environmental Responsibility: The system’s environmentally conscious design helps businesses meet regulatory requirements while promoting sustainable and eco-friendly practices.

The Precious Metal Refining System represents a state-of-the-art solution for businesses seeking to enhance their gold refining processes.

With its superior performance, energy efficiency, and commitment to sustainability, it is the ideal choice for achieving the highest quality refined products, maximizing profitability, and ensuring long-term operational success.

Frequently Asked Questions (FAQ)

1. What types of materials can the Precious Metal Refining System process?

The system is designed to refine a variety of gold-bearing materials, including carat gold scrap, filings, polishing dust, and other precious metal alloys such as silver, platinum, and palladium. It is versatile enough to handle both large and small quantities of gold-bearing materials efficiently.

2. How pure is the gold after refining?

The system consistently achieves gold purity levels ranging from 999.5 to 999.9 parts per thousand (99.95% to 99.99%), ensuring exceptional quality that meets industry standards for high-value applications.

3. What is the maximum batch size that the system can process?

The Precious Metal Refining System can handle batch sizes ranging from 1 kg to 100 kg, offering flexibility to accommodate both small-scale and large-scale refining operations.

4. How many batches can the system process in a day?

The system is optimized for high throughput and can process up to 3 batches within a 24-hour cycle, maximizing production capacity while maintaining high standards of quality and efficiency.

5. Is the system energy-efficient?

Yes, the system is designed with optimal energy efficiency in mind. It minimizes energy consumption without compromising performance, making it a cost-effective solution for long-term use.

6. What type of electrical supply is required to operate the system?

The system is compatible with standard 3-phase electrical power systems, making it easy to integrate into most industrial settings. It operates reliably within these standard electrical parameters.

7. What types of refining processes are used in the system?

The system utilizes advanced refining technologies, which may include electrolytic and chemical methods, to effectively remove impurities and achieve the desired purity levels. These methods ensure precise and efficient processing.

8. How environmentally friendly is the system?

The system is engineered to meet stringent environmental standards and minimize its environmental impact. It adheres to pollution control regulations and promotes eco-friendly practices throughout the refining process.

9. Is the system easy to install and operate?

Yes, the system is designed for straightforward installation and user-friendly operation. It comes equipped with intuitive controls and a monitoring system, enabling operators to easily optimize the refining process.

10. What safety features does the system include?

The system incorporates a comprehensive range of safety mechanisms to protect operators and prevent accidents. These features include emergency shut-off systems, temperature and pressure monitoring, and automatic alerts to ensure safe operation.

11. Can the system be customized to meet specific needs?

Yes, the Precious Metal Refining System offers customization options to meet the unique requirements of your business. Whether you need adjustments in batch sizes, processing methods, or specific features, we can tailor the system to your exact specifications.

12. What kind of maintenance is required for the system?

The system is designed with minimal maintenance requirements. Routine checks and periodic servicing are all that’s needed to ensure optimal performance. The system’s durable construction and quality components contribute to its long operational lifespan with minimal downtime.

13. How long can I expect the system to last?

Built with high-quality materials and components, the system is designed for long-term reliability and durability. With proper care and maintenance, it can provide many years of continuous, efficient operation.

14. Does the system come with a warranty?

Yes, the Precious Metal Refining System comes with a standard warranty that covers defects in materials and workmanship. Please refer to the product documentation for detailed warranty terms and conditions.

15. Is training provided for operators?

Yes, we offer comprehensive training for operators to ensure that they are fully equipped to use the system effectively. Our training program covers system operation, safety protocols, and process optimization to ensure maximum efficiency and safety.