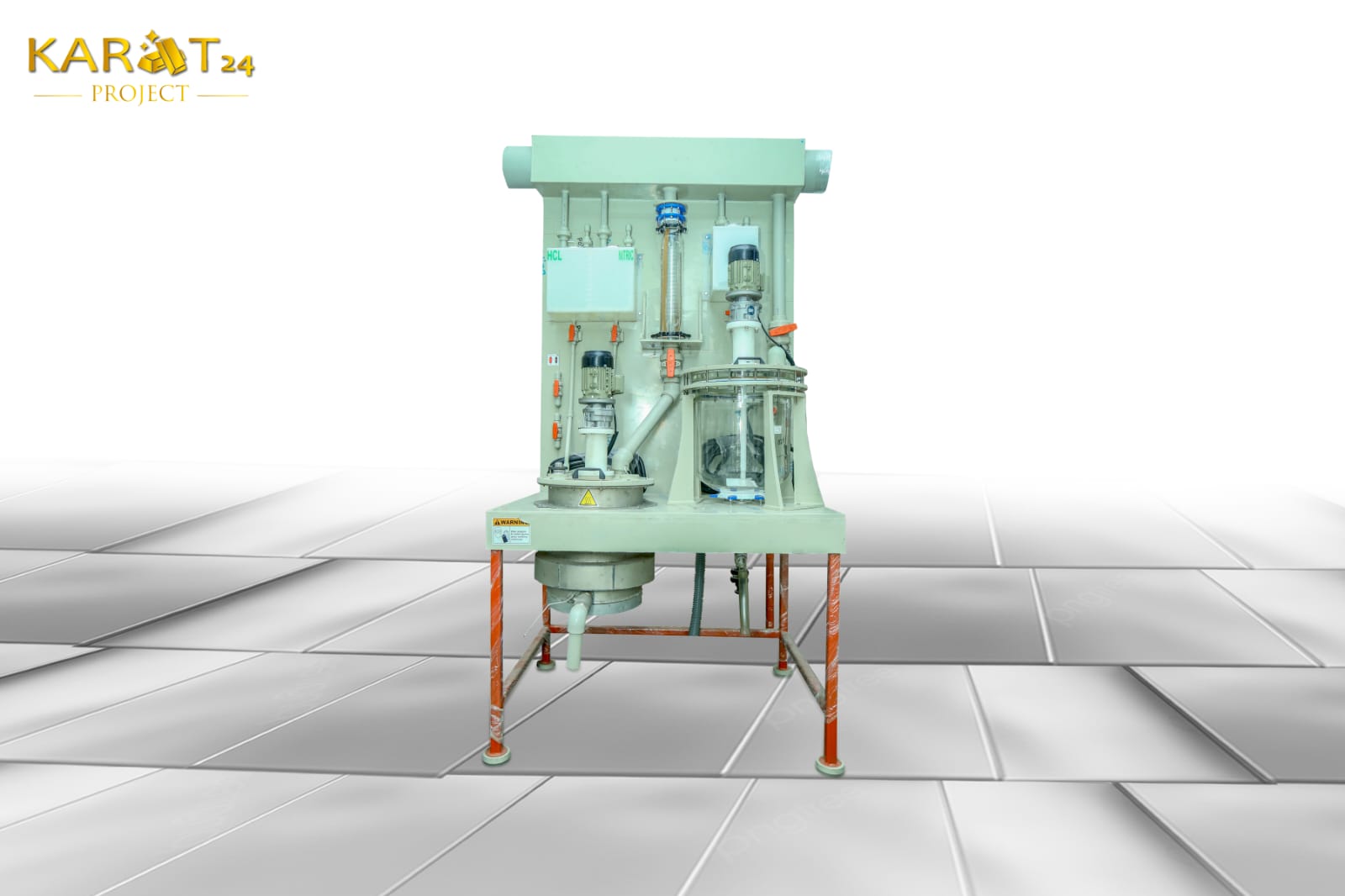

Gold Jewellery Refining System

This sophisticated Gold Jewellery Refining System has been meticulously designed to ensure the highest efficiency and purity in the recovery of precious metals.

Ideal for processing a variety of materials—ranging from filings, polishing residues, dust, and other scraps generated during jewellery production or repair—the system is a must-have for any business seeking to optimize its precious metal recovery processes.

Key Features and Benefits:

- High-Efficiency Refining:

- Employs cutting-edge electrochemical and/or pyrometallurgical technologies to ensure near-total recovery of precious metals, reducing the loss of valuable material during the refining process.

- Engineered to maximize yield while maintaining operational efficiency, ensuring minimal wastage and higher profitability.

- High Purity Output:

- Capable of refining gold to exceptionally high purity levels, ranging from 999.5 to 999.9/1000, far exceeding industry standards.

- The refined metals produced are ideal for reintegration into jewellery production or investment-grade purposes, ensuring that your output always meets the highest-quality demands.

- Robust and Durable Construction:

- Crafted from premium, corrosion-resistant materials, this system is designed for long-term performance in demanding industrial environments.

- Its sturdy build ensures low-maintenance operation, even under rigorous use, reducing downtime and extending the lifespan of the equipment.

- Customizable Capacity:

- Available in a wide range of models with alloy batch charge capacities from 1 kg to 100 kg, allowing for flexibility in scale—from small jewellery shops to large-scale industrial operations.

- This versatility ensures that businesses of all sizes can find an optimal solution that aligns with their unique needs.

- Optimized Working Cycle:

- The system is engineered for maximum throughput, enabling up to 3 batches per 24-hour cycle, which translates to faster recovery times and enhanced productivity.

- Quick turnaround times help businesses to operate more efficiently, ultimately boosting profitability by minimizing idle times.

- Advanced Control Systems:

- Integrated with intuitive, user-friendly control panels for real-time monitoring and precise adjustments of all refining parameters.

- This system ensures consistent and repeatable results with minimal operator error, improving the overall reliability of your operations.

- Safety and Environmental Considerations:

- Designed with built-in safety mechanisms, ensuring protection for operators and the environment throughout the refining process.

- The system minimizes hazardous emissions and waste, promoting sustainability and aligning with environmental best practices for responsible refining.

- Electrical Specifications:

- Operates on a standard 3-phase electrical power supply, making it compatible with most industrial power systems.

- The system is energy-efficient, offering high performance while minimizing operational costs.

Applications:

- Jewellery Manufacturing Facilities: Ideal for high-volume recovery of precious metals from production scrap and waste.

- Gold Refineries: A key tool for professional refining operations to extract maximum value from precious metal residues.

- Precious Metal Recycling Centers: Perfect for businesses focused on recycling precious metals from a variety of sources, including consumer goods and industrial by-products.

- Assay Offices and Laboratories: A critical tool for accurately refining and purifying precious metals, ensuring accuracy in testing and valuation.

Technical Specifications:

- Alloy Batch Charge: 1 kg to 100 kg (depending on model)

- Working Cycle Time: Capable of processing up to 3 batches within a 24-hour period

- Purity Achievable: 999.5 to 999.8-9/1000

- Electrical Power Supply: 3-phase

- Refining Method: Electrochemical and/or Pyrometallurgical techniques

Benefits for Clients:

- Increased Profitability: Maximize precious metal recovery with high-efficiency processes, reducing material loss and boosting returns.

- Reduced Material Costs: Turn waste and scrap into valuable resources, significantly lowering costs through efficient recycling and recovery.

- Enhanced Product Quality: Achieve the highest purity metals for top-tier jewellery production or investment-grade materials.

- Improved Operational Efficiency: Fast cycle times and user-friendly controls streamline your production process, increasing overall productivity.

- Sustainable Practices: Minimize environmental impact with eco-friendly designs and minimal waste production.

- Reliable and Long-Lasting Equipment: Designed for continuous operation with minimal downtime, ensuring your investment is protected for the long term.

Customization Options:

We understand that each client’s needs are unique, and we offer tailored solutions to meet specific refining requirements. Customizations include:

- Refining Capacity: Choose from various batch sizes to suit the scale of your operation, whether small or large.

- Automation Levels: Select from manual to fully automated systems for the perfect balance of control and convenience.

- Refining Process Options: Choose between electrochemical or pyrometallurgical processes—or a combination of both—to suit your specific material inputs and desired outcomes.

By tailoring the system to your precise needs, we ensure the highest level of efficiency and profitability for your business.

This Gold Jewellery Refining System offers businesses an unmatched opportunity to recover precious metals with precision, efficiency, and sustainability.

Whether you’re refining materials for jewellery production or investment purposes, this system delivers the reliability and performance your operations demand.

Sure! Here’s a set of Frequently Asked Questions (FAQ) that you can add to your product description:

Frequently Asked Questions (FAQ)

1. What types of materials can the refining system process?

- The system is designed to process a variety of materials commonly encountered in the jewellery industry, including filings, polishing residues, dust, and other scrap metals generated during manufacturing and repair processes. It is particularly effective for gold but can also handle various metal alloys with proper adjustments.

2. What is the maximum capacity of the refining system?

- The refining system is available in different models with batch charge capacities ranging from 1 kg to 100 kg, catering to businesses of all sizes—from small jewellery workshops to large-scale industrial operations. Please consult with our team to find the best model for your specific needs.

3. How pure is the refined gold ?

- Our refining system can achieve extremely high purity levels, with gold refined to purities between 999.5 and 999.9/1000, which meets and often exceeds industry standards.

4. How long does the refining process take?

- The system is designed to allow for up to three refining batches within a 24-hour working cycle, ensuring quick turnaround times and high productivity. The exact time per batch may vary depending on the material and refining process used.

5. Is the system easy to operate?

- Yes, the system features an intuitive and user-friendly control interface, allowing operators to monitor and adjust refining parameters with ease. With advanced control systems, consistency and precision are guaranteed, reducing the risk of operator error.

6. What safety features are included in the system?

- The refining system is equipped with several safety mechanisms to protect operators. These include automatic shut-offs, pressure and temperature monitoring, and secure handling systems for hazardous materials. Additionally, the system is designed to minimize harmful emissions and waste, adhering to environmental safety standards.

7. Does the system require specialized training to operate?

- While the system is designed to be user-friendly, we recommend providing your operators with basic training to ensure safe and efficient use. Training can be arranged through our support team upon installation.

8. What are the power requirements for the system?

- The system operates on a standard 3-phase electrical power supply, making it compatible with most industrial power systems. We will assist you with the power specifications upon ordering to ensure compatibility with your facility.

9. Can the system be customized to suit specific refining needs?

- Absolutely! We offer customization options based on your specific requirements. Whether you need a certain refining capacity, level of automation, or specific process preferences (electrochemical vs. pyrometallurgical), our team can work with you to create a tailored solution.

10. What kind of maintenance is required for the system?

- The system is built with durability and reliability in mind, requiring minimal maintenance. Regular maintenance mainly involves cleaning the system, checking for wear on components, and ensuring all safety features are operational. We provide detailed maintenance guidelines, and our support team is available for any assistance.

11. Is the refining system environmentally friendly?

- Yes, the system is designed with sustainability in mind. It minimizes waste and emissions during the refining process and ensures that the refining of precious metals is conducted in an eco-friendly manner. Additionally, our system promotes the recycling of scrap materials, reducing environmental impact.

12. Can the refined metal be used directly in jewellery production?

- Yes! The refined gold produced by the system are of high enough purity to be directly reused in jewellery manufacturing, ensuring that the metals meet the quality standards required for high-end pieces and investment purposes.

13. What support is available after purchasing the system?

- We offer comprehensive after-sales support, including installation assistance, operator training, and ongoing technical support. Our team is available to assist with any troubleshooting, upgrades, or customization needs to ensure optimal operation of the system throughout its lifespan.