Maximize Gold Recovery & Purity with Our Advanced Filtration Unit

The Refining Challenge:

Gold refineries operate in a highly demanding and competitive environment where efficiency, profitability, and product quality are paramount. A significant challenge that gold refineries face is the difficulty of separating precious gold particles from various refining solutions.

These solutions, often laden with impurities such as metals, chemicals, and other residues, complicate the filtration process and can lead to substantial gold loss. Traditional filtration methods, while still in use in many refineries, are often slow, inefficient, and prone to inaccuracies that can undermine both gold recovery and purity.

Not only do these methods increase the risk of contamination and result in gold loss, but they also prolong processing times, thereby slowing down throughput and lowering overall production capacity.

With refineries under constant pressure to improve yields, reduce operational costs, and meet stricter purity standards, the demand for more advanced filtration solutions has never been higher.

The Solution:

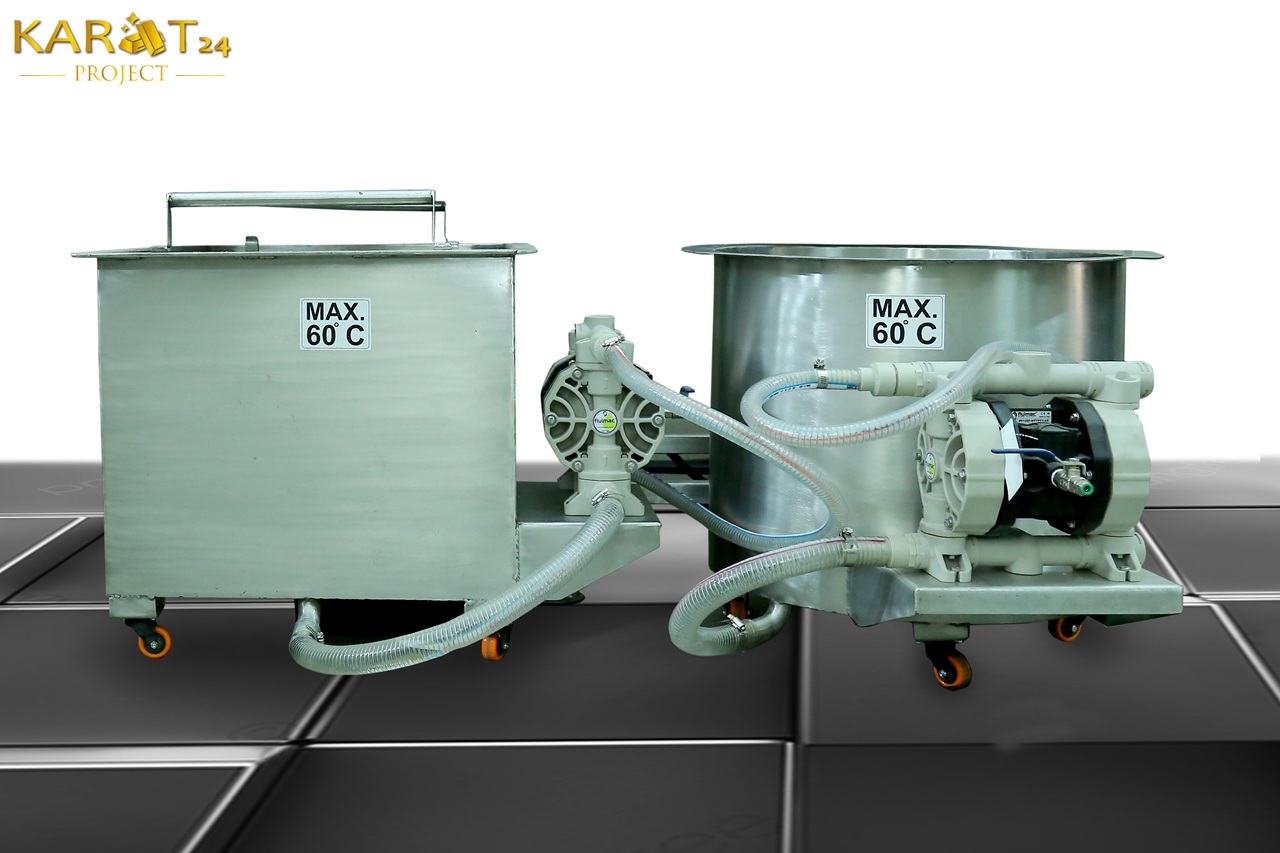

Our specialized liquid filtration unit has been specifically engineered to address the complex challenges of gold refining. By offering state-of-the-art filtration technology, we deliver a solution that ensures maximum gold recovery and uncompromised purity, while also optimizing processing time and reducing operational costs.

Designed for high-performance and reliability, this filtration unit stands out in its ability to deliver superior results in the most demanding refining environments. Let’s take a closer look at how our filtration unit tackles these critical challenges.

Key Features & Benefits (Tailored for Gold Refineries):

1. High-Efficiency Gold Particle Retention:

One of the most crucial aspects of any filtration system in a gold refinery is its ability to capture even the finest gold particles.

Traditional filters often allow smaller gold particles to escape or become lost in the filtration media, resulting in significant losses.

- Precision-Engineered Filtration Media: Our filter uses high-quality PP (Polypropylene) and/or paper filter sheets, specifically selected for their exceptional ability to retain gold particles of all sizes. These materials are engineered to provide optimal particle retention without compromising flow rates or filtration efficiency.

- Minimizing Gold Loss: The advanced design of our filtration media ensures that even the smallest gold particles are captured, effectively minimizing gold loss during the filtration process. This results in higher yields and improved profitability for refineries, as more of the precious metal is recovered and purified.

With these enhanced particle retention capabilities, our filtration unit provides a direct solution to one of the most common challenges faced by gold refineries—maximizing recovery and minimizing the loss of valuable gold during the filtration process.

2. Robust and Chemically Resistant Construction:

Gold refining often involves the use of highly corrosive chemicals, such as acids and cyanides, which can quickly degrade traditional filtration equipment.

Given the critical need for reliability in these harsh environments, the construction materials used in our filtration system are of the highest quality.

- Corrosion-Resistant Materials: Our filtration unit is constructed from high-quality Plastic PP, a material known for its remarkable resistance to corrosion and wear, even when exposed to highly acidic or alkaline solutions. This construction ensures that the filter retains its integrity and functionality, even in the harshest conditions typical of gold refining processes.

- Long-Lasting Durability: Thanks to its durable, chemically resistant design, the filtration unit is able to withstand prolonged use in challenging environments. This reduces the frequency of repairs and replacements, cutting down on maintenance costs and extending the life of the equipment.

The use of high-quality, corrosion-resistant materials not only boosts the long-term reliability of the filtration unit but also enhances operational efficiency by reducing downtime and maintenance needs.

3. Optimized Vacuum Filtration for Speed and Efficiency:

Time is money in the gold refining industry. The faster the filtration process, the greater the throughput and the higher the potential for profitability.

Our filtration unit is designed to accelerate filtration cycles, allowing for quicker processing times and enhanced production efficiency.

- High-Performance Vacuum Filtration: Our system is equipped with a powerful air diaphragm pump featuring PP construction, providing consistent suction power to draw liquids through the filter media efficiently. This pump is paired with interchangeable PTFE (Polytetrafluoroethylene) membranes that ensure maximum filtration efficiency and minimal resistance to flow.

- Faster Filtration Cycles: The combination of powerful vacuum filtration and optimized pump design allows our unit to filter solutions more quickly than traditional methods. This reduces processing time, speeds up gold recovery, and allows your refinery to increase throughput and overall production capacity.

By dramatically reducing filtration time, our system contributes to faster turnarounds, allowing refineries to process larger volumes of material in a shorter time, which translates directly into increased profitability.

4. Contamination Control for Superior Purity:

In the gold refining process, maintaining the purity of the final product is paramount. Any contamination from chemicals, metals, or residues can undermine the value of the refined gold.

Our filtration unit incorporates several advanced features designed to control contamination, ensuring that the final product is of the highest purity.

- Airborne Contamination Prevention: The filtration unit is equipped with an integrated fume extraction suction plug, which works in tandem with the enclosed system design to minimize the risk of airborne contamination. This ensures that impurities do not enter the refining environment, keeping the gold solution pure throughout the filtration process.

- Vacuum Breaker Valve for Safety: The inclusion of a vacuum breaker valve adds another layer of protection, preventing potential equipment failure due to overpressure or implosion. This feature not only improves safety but also ensures that the system operates efficiently without the risk of contamination or malfunction.

These combined features significantly contribute to maintaining high purity levels in the final gold product, an essential factor for meeting market demands for refined gold of superior quality.

5. Mobility and User-Friendly Design:

Flexibility and ease of use are key considerations for any refinery looking to optimize its operations. The mobility of the filtration unit allows it to be integrated into existing refinery setups, while also facilitating easy relocation within the facility to accommodate changing workflows.

- Trolley-Mounted Design with Pivoting Wheels: The filtration unit is mounted on a trolley with pivoting wheels, making it easy to move the system to different locations within the refinery. This mobility allows refineries to adapt quickly to production demands and refine multiple batches with ease.

- Easy Integration: The unit comes equipped with ON/OFF ball valves that allow for seamless integration into existing refinery lines. Whether upgrading existing filtration systems or expanding operations, the filtration unit can be quickly and easily integrated without significant disruption to ongoing production.

The combination of mobility and user-friendly design enhances the flexibility and operational efficiency of the refinery, ensuring that the filtration process can be managed with minimal hassle and downtime.

6. Customizable Filtration Media for Versatile Applications:

Every gold refining process is unique, and different types of solutions may require varying filtration media to achieve optimal results.

Our filtration unit is designed with customizability in mind, giving refineries the flexibility to choose the ideal filter media for their specific application.

- Adjustable Pore Size: The filtration system is designed to accommodate a range of filter media types, allowing for the customization of pore sizes depending on the application. This ensures that the filtration process is tailored to the specific needs of your refinery, whether you are processing fine gold particles or dealing with larger debris.

- Versatile Media Selection: Whether you are refining different grades of gold or working with diverse solution types, the filtration unit offers a versatile solution that adapts to your unique requirements.

This level of customizability ensures that the filtration unit can provide the best possible performance, no matter the nature of the materials being processed.

Value Proposition:

By incorporating our advanced filtration unit into your gold refining process, you gain access to a number of key benefits that directly contribute to improved profitability, increased operational efficiency, and superior product quality:

- Maximized Gold Recovery: The highly efficient particle retention system reduces gold loss, enabling higher yields and increased profitability.

- Improved Gold Purity: With advanced contamination control features, the filtration unit ensures the production of high-purity gold that meets market standards.

- Faster Processing Times: The optimized vacuum filtration system accelerates the filtration process, allowing for greater throughput and more efficient operations.

- Lower Operating Costs: Durable, chemically resistant construction and energy-efficient operation reduce maintenance and energy consumption, leading to cost savings.

- Enhanced Safety: The enclosed system and vacuum breaker valve contribute to a safer working environment by minimizing the risk of accidents and contamination.

Optimize your gold refining process and increase your profitability with our state-of-the-art filtration unit. Designed for maximum gold recovery, superior purity, and enhanced operational efficiency, this filtration system is the key to refining success.

Contact us today to schedule a personalized consultation and learn how our advanced filtration solution can address your specific refining needs. Unlock your refinery’s full potential and ensure your competitive edge in the industry.