High-Efficiency Fume Scrubber for Precious Metal Refinery

Problem:

Precious metal refining is a critical yet highly complex process that serves various industries, including electronics, jewelry, automotive, and medicine.

While essential, it also produces a range of hazardous byproducts in the form of toxic fumes, dust, and gases. These pollutants pose significant risks to both the environment and the health of workers in the refinery, as well as the surrounding communities. Common emissions generated during precious metal refining include:

- Acid Vapors: These include nitric acid, hydrochloric acid, and sulfuric acid vapors, which are highly corrosive. These fumes can irritate the respiratory system, damage lung tissue, and corrode equipment. Prolonged exposure can cause severe respiratory issues, including asthma and chronic obstructive pulmonary disease (COPD). They also create environmental damage by contaminating air, soil, and water systems.

- Metal Oxides: During refining, the combustion of precious metals such as gold, platinum, and palladium results in the production of metal oxides. These toxic particles, often sub-micron in size, can be inhaled and lead to serious health issues, including lung damage and metal poisoning.

- Nitrogen Oxides (NOx): These gases, primarily nitrogen dioxide (NO2) and nitric oxide (NO), contribute significantly to air pollution. They are responsible for the formation of acid rain and smog, which have detrimental effects on both human health and the environment. NOx also exacerbates the greenhouse effect and global warming, leading to long-term atmospheric changes.

- Volatile Organic Compounds (VOCs): VOCs released from refinery operations produce unpleasant odors and can be harmful when inhaled. VOCs are often linked to headaches, nausea, dizziness, and more serious long-term health effects, including cancer. Additionally, VOCs contribute to the formation of ground-level ozone, which is a key component of smog.

Current fume scrubbing solutions struggle to effectively address these issues, leading to several challenges for the refining industry:

- Inefficient Pollutant Removal: Many traditional fume scrubbers fail to capture and neutralize all of the hazardous pollutants, allowing harmful emissions to escape into the atmosphere.

- High Energy Consumption: Many existing scrubbing systems are inefficient, consuming large amounts of energy in order to operate. This leads to inflated operational costs and a higher carbon footprint for refineries.

- Maintenance and Durability Issues: Traditional scrubbers are prone to wear and tear, requiring frequent maintenance, leading to system downtimes and increased operational costs.

- Regulatory Compliance Issues: Stricter environmental regulations across the globe require refining operations to maintain stringent emissions standards. Many current scrubbers fail to meet these evolving standards, which could lead to fines and other penalties.

- Health and Safety Risks for Workers: Inadequate scrubbing solutions can allow dangerous pollutants to accumulate in the workplace, leading to health hazards for workers and lowering overall productivity due to sickness or exposure.

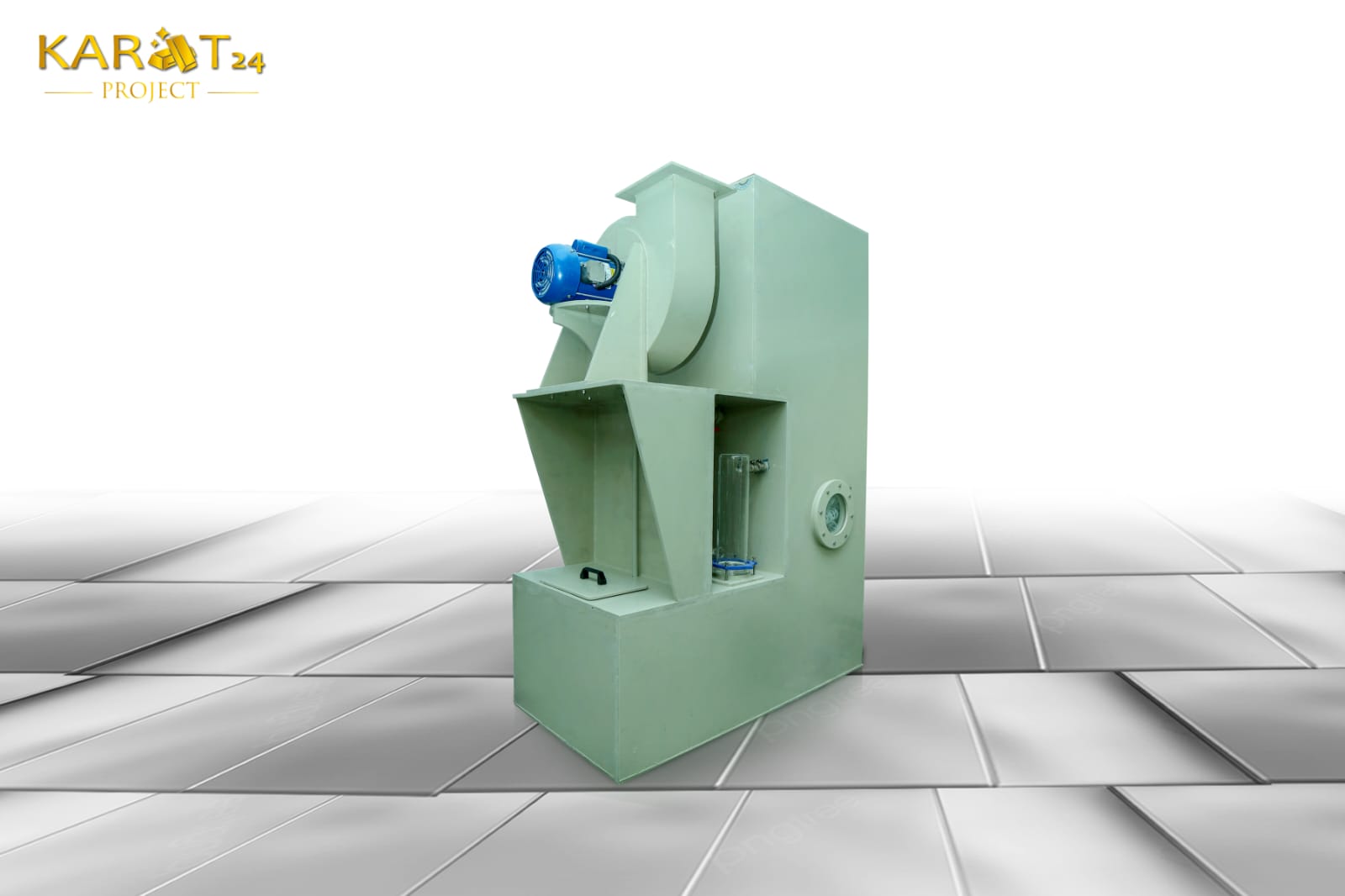

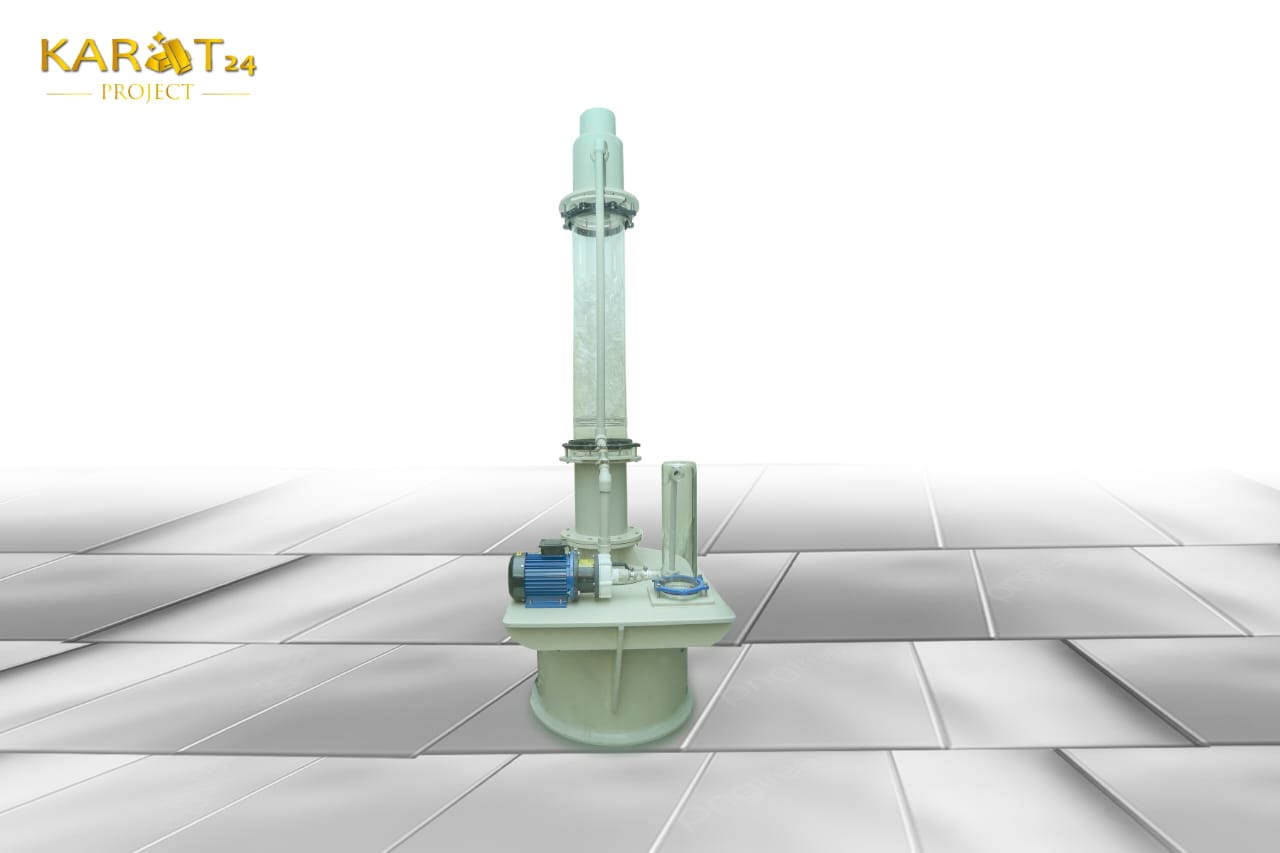

Solution: High-Efficiency Fume Scrubber System

Our innovative High-Efficiency Fume Scrubber System addresses these problems with cutting-edge technology, ensuring cleaner air, healthier work environments, and regulatory compliance.

This advanced air purification system is specifically designed for the demanding environment of precious metal refineries, offering superior performance in removing pollutants, enhancing energy efficiency, and improving long-term operational reliability.

Key features of our High-Efficiency Fume Scrubber System include:

Superior Pollutant Removal:

- Advanced Wet Scrubbing Technology: At the heart of our fume scrubber is state-of-the-art wet scrubbing technology that uses highly effective scrubber liquids to neutralize a wide range of harmful gases, including acid vapors and metal oxides. The scrubbing process is optimized by advanced packing materials that maximize the surface area for contact between the liquid and the fumes, significantly increasing the efficiency of pollutant removal. This allows for near-complete capture of hazardous emissions.

- Chemical Neutralization Stages: The scrubber features multiple stages of chemical neutralization, each tailored to specific pollutants commonly found in precious metal refining operations. For example, one stage may neutralize acidic vapors, while another may target the reduction of metal oxides. This multi-stage approach ensures that all contaminants are effectively neutralized or captured, reducing the risk of harmful substances escaping into the atmosphere.

- HEPA Filtration: High-Efficiency Particulate Air (HEPA) filters are employed to capture ultra-fine particulate matter, including metal oxides. These filters are capable of trapping particles as small as 0.3 microns, ensuring that harmful dusts like platinum and palladium oxides are completely filtered from the air, safeguarding workers and the environment.

- Activated Carbon Filtration: To effectively capture volatile organic compounds (VOCs) and odors, our system incorporates activated carbon filtration. Activated carbon is highly effective at adsorbing VOCs, ensuring that any odorous gases or potentially harmful compounds are fully neutralized before being released into the environment.

Energy Efficiency:

- Intelligent Control Systems: The system features intelligent sensors and algorithms that monitor air quality and adjust fan and pump speeds in real-time. This dynamic control ensures that energy consumption is kept to a minimum without compromising the performance of the scrubber. This reduces the energy required to run the system, cutting operational costs while minimizing the carbon footprint of the refinery.

- Heat Recovery System: Our scrubber system integrates heat recovery mechanisms to harness waste heat generated during the scrubbing process. This heat can be recycled to preheat incoming air or water, lowering the overall energy consumption required for the system. By utilizing heat that would otherwise be wasted, we further reduce operational costs and improve the system’s environmental performance.

Robust and Reliable Design:

- Corrosion-Resistant Materials: The scrubber is constructed from high-quality, corrosion-resistant materials that are designed to withstand the harsh, acidic conditions typical in a precious metal refinery. This ensures that the system will operate effectively over a long period without experiencing significant degradation, reducing the need for costly repairs and replacements.

- Modular Design: The scrubber is modular in design, allowing for easy scaling and customization to meet the specific needs of individual refineries. This flexibility ensures that the system can be adapted to changing production demands, emissions outputs, or facility expansions, making it a future-proof solution for refineries of any size.

- Automated Monitoring and Control Systems: The scrubber is equipped with advanced sensors and automated monitoring systems that track the performance of the system in real-time. This enables refinery operators to detect any issues early and take corrective action before they lead to system failures or downtime. Automated control systems also ensure that the scrubber operates at peak efficiency at all times.

Compliance and Safety:

- Regulatory Compliance: Our High-Efficiency Fume Scrubber System is designed to meet or exceed all relevant environmental regulations and industry standards. From local air quality regulations to international standards such as the Clean Air Act, our system ensures that refineries remain compliant with evolving regulatory requirements, helping them avoid costly fines and penalties.

- Worker Health and Safety: By capturing and neutralizing toxic fumes, dust, and gases, the system ensures a safer and healthier work environment. With reduced exposure to hazardous substances, refineries can improve worker well-being, reduce absenteeism due to illness, and enhance overall productivity. The scrubber system contributes to a workplace where employees feel confident in their safety, improving morale and retention.

- Data Logging and Reporting: The scrubber system comes with built-in data logging and reporting capabilities, which automatically track the emissions captured by the system. This data can be used to generate compliance reports, track system performance, and identify potential areas for improvement. This ensures that the refinery stays ahead of regulatory requirements while maintaining full transparency in their operations.

Customization:

Every refinery has unique needs, from specific pollutants to varying emissions volumes and operational configurations. Our High-Efficiency Fume Scrubber System can be customized to meet these needs. Whether the refinery needs a system designed to handle high levels of acid vapors or one optimized for VOC capture, we tailor our solution to fit.

Value Proposition:

Investing in our High-Efficiency Fume Scrubber System offers a range of benefits:

- Reduced Environmental Impact: By efficiently capturing and neutralizing harmful pollutants, our system reduces emissions, helping refineries contribute to a cleaner, more sustainable environment.

- Improved Worker Health and Safety: With better air quality and fewer toxic fumes, workers benefit from a safer, healthier environment, reducing the risk of illness and enhancing workplace productivity.

- Lower Operating Costs: Through energy optimization, reduced maintenance needs, and minimal downtime, our scrubber system helps refineries achieve cost savings over the long term.

- Enhanced Regulatory Compliance: With a system designed to meet or exceed environmental standards, refineries avoid the risk of fines and stay ahead of evolving regulations, ensuring continuous compliance.

- Increased Operational Efficiency: Our scrubber system reduces downtime, improves air quality, and optimizes energy use, boosting overall operational efficiency and productivity.

Act Now:

Transform your precious metal refining operation into a cleaner, safer, and more efficient facility with our High-Efficiency Fume Scrubber System. Contact us today for a consultation and customized solution tailored to your unique needs.

Let us help you achieve superior air quality, regulatory compliance, and long-term cost savings while protecting the environment and your workforce. Together, we can build a more sustainable and profitable future for your refinery.