Revolutionize Your Precious Metal Refinery with Advanced Polypropylene Fabrication Solutions

The Challenges Facing Precious Metal Refineries:

Precious metal refineries are vital hubs for extracting and refining valuable metals such as gold, silver, platinum, and palladium. However, these facilities face a series of complex challenges that can significantly impact their efficiency, safety, and profitability. Among the most pressing issues are:

1. Corrosion:

The refining process often requires the use of highly corrosive chemicals and acids, such as aqua regia, sulfuric acid, and hydrochloric acid.

These substances are essential for extracting precious metals from ores, but they also wreak havoc on equipment and infrastructure.

Over time, corrosion leads to the degradation of critical components like tanks, piping systems, and reaction vessels, resulting in costly repairs, replacements, and prolonged downtime.

2. Safety Hazards:

The handling of hazardous chemicals, coupled with the high-temperature processes involved in refining, presents significant safety risks for workers. Leaks, spills, and exposure to harmful fumes or chemicals can lead to serious accidents, health issues, and even fatalities.

Ensuring a safe environment for personnel is a top priority, and existing equipment often fails to meet the required safety standards or becomes compromised over time.

3. Operational Inefficiencies:

Traditional materials, such as steel and concrete, while robust, can become inefficient over time. For instance, they can corrode or degrade under the harsh conditions of a refinery, leading to increased maintenance needs, higher energy consumption, and even product loss.

Refiners often find themselves dealing with slow processing times, inefficient throughput, and bottlenecks that reduce overall productivity.

4. Purity Concerns:

In the precious metals industry, purity is everything. Even the smallest trace of contamination can compromise the quality of refined metals, reducing their value.

Traditional materials and outdated equipment are often culprits in introducing impurities during the refining process, which not only affects the value of the end product but can also damage the reputation of a refinery.

Introducing Polypropylene Fabrication: The Superior Alternative

We offer a transformative solution to the numerous challenges faced by precious metal refineries: advanced polypropylene fabrication. Polypropylene (PP) is a highly durable, chemically resistant, and cost-effective thermoplastic polymer that has revolutionized industries worldwide.

It is particularly well-suited for the demanding environment of precious metal refineries, offering a range of advantages over traditional materials like steel, concrete, and fiberglass.

What is Polypropylene Fabrication?

Polypropylene fabrication involves creating custom-engineered systems and equipment from polypropylene, a material renowned for its outstanding chemical resistance, durability, and versatility.

By using advanced fabrication techniques, we design and manufacture a wide range of solutions tailored specifically for the precious metal refining industry. These solutions are not only more durable and safe but also cost-effective in the long run.

Our Product Offerings:

We provide a comprehensive range of custom polypropylene products and systems designed to address the unique challenges of precious metal refineries.

Our solutions are engineered to ensure maximum efficiency, safety, and longevity while minimizing maintenance costs and operational downtime.

1. Custom Tanks and Vessels:

We offer a variety of custom polypropylene tanks and vessels that are specifically designed for the corrosive processes in precious metal refining. These include acid digestion tanks, leaching tanks, electrorefining cells, and more.

Each tank is engineered to withstand the harsh chemicals involved in refining processes, such as sulfuric acid, nitric acid, and aqua regia. These tanks are built for longevity, providing years of reliable service without the risk of corrosion or material degradation.

2. Piping Systems:

Our corrosion-resistant polypropylene piping systems are perfect for the safe and efficient transfer of corrosive liquids and gases throughout the refinery.

Polypropylene’s chemical resistance ensures that it can handle a wide range of substances without deteriorating, minimizing the risk of leaks and spills. Additionally, the smooth internal surfaces of our piping systems optimize flow rates, reducing energy consumption and improving process efficiency.

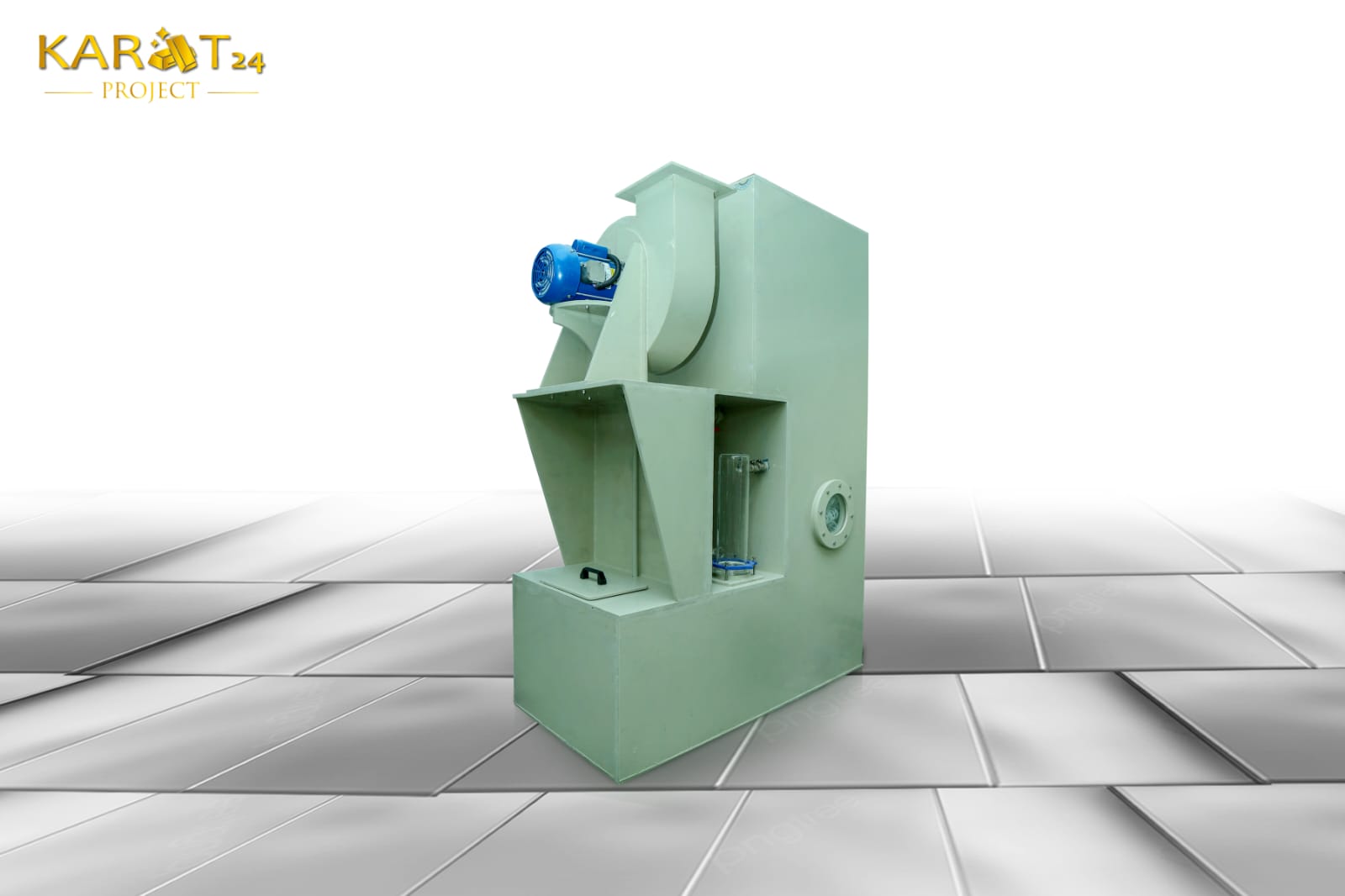

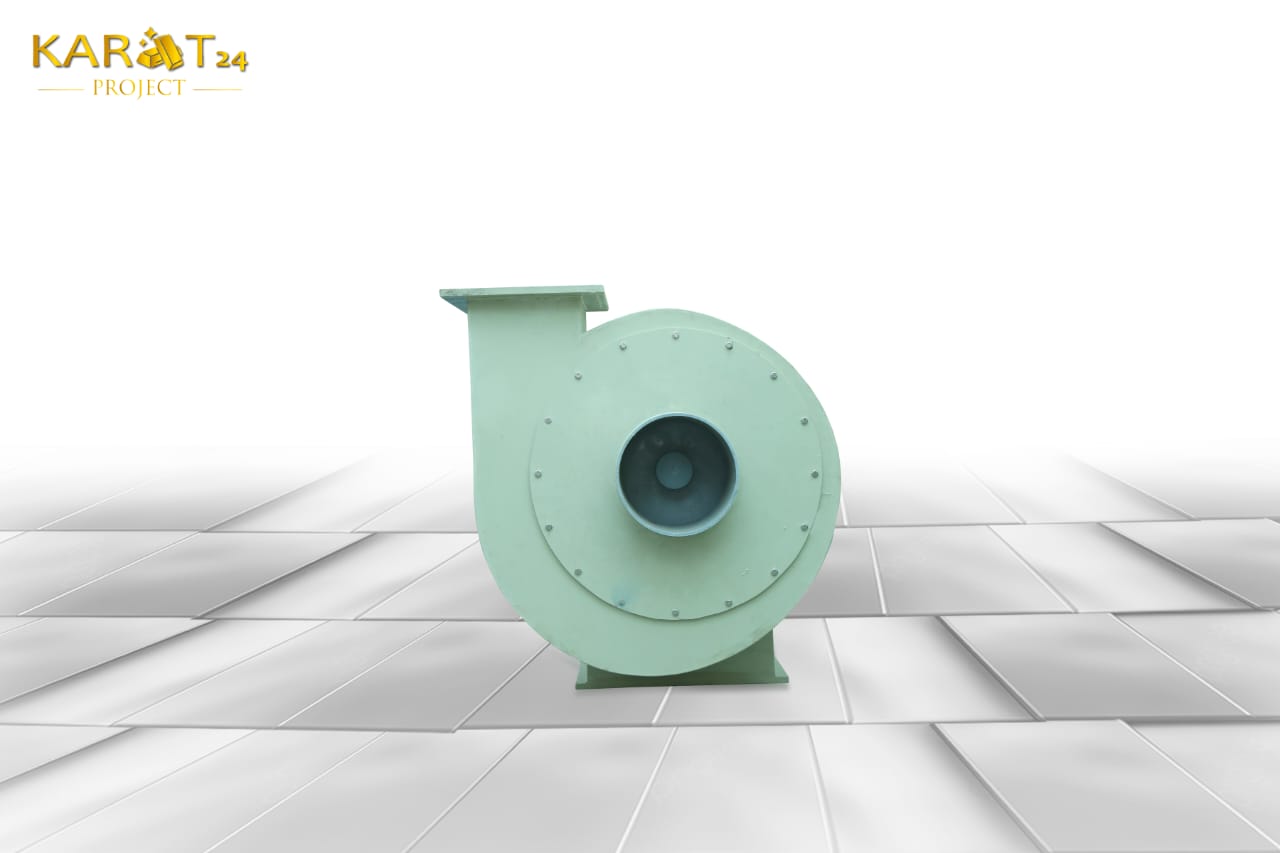

3. Fume Hoods and Scrubbers:

Fumes generated during the refining process can be harmful to both workers and the environment. Our polypropylene fume hoods and scrubbers are designed to safely capture and neutralize hazardous fumes.

These systems provide effective ventilation and air purification, ensuring compliance with environmental regulations and maintaining a safe working atmosphere for refinery personnel.

4. Protective Liners and Coatings:

Polypropylene liners and coatings are an excellent solution for extending the life of existing concrete or steel tanks. These protective layers prevent corrosion and chemical damage, preserving the integrity of your equipment and reducing the need for costly repairs or replacements.

Our custom liners are tailored to fit any existing infrastructure, providing a seamless and durable solution for tanks of all sizes.

5. Custom Equipment Solutions:

In addition to standard products, we specialize in designing and fabricating custom equipment solutions to meet the specific needs of each refinery.

Whether it’s a custom reaction vessel, filtration system, or any other specialized component, our team of engineers works closely with clients to develop equipment that fits seamlessly into their operations.

This ensures that your refinery can continue to operate efficiently, with minimal disruption to your workflow.

Key Benefits of Polypropylene Fabrication:

Polypropylene fabrication offers several key advantages that make it the ideal choice for precious metal refineries:

1. Exceptional Chemical Resistance:

Polypropylene stands out for its incredible resistance to a wide range of acids, alkalis, and other corrosive chemicals commonly used in precious metal refining. Unlike traditional materials like steel, which can corrode quickly, polypropylene remains impervious to damage from even the most aggressive substances.

This chemical resistance ensures that your equipment remains in optimal condition throughout its lifespan.

2. Superior Durability and Longevity:

Polypropylene is a highly durable material that can withstand the wear and tear of the refining process without breaking down or losing its integrity.

Our fabrication techniques ensure that all products are built to last, reducing the need for frequent repairs and replacements. The result is a significant reduction in downtime and maintenance costs, allowing your refinery to operate more efficiently.

3. Enhanced Safety:

Polypropylene equipment reduces the risk of leaks, spills, and chemical exposure, which helps create a safer work environment.

The robust design of our tanks, piping, and other components minimizes the likelihood of accidents, while the smooth surfaces of polypropylene prevent the buildup of hazardous residues. This translates into a safer environment for workers and better compliance with safety regulations.

4. Improved Operational Efficiency:

Polypropylene’s smooth, non-reactive surface ensures efficient material flow and reduces friction, which helps optimize throughput and minimizes product loss.

Additionally, the lightweight nature of polypropylene makes installation quicker and easier, reducing labor costs and installation downtime.

By improving efficiency across your refinery’s operations, polypropylene fabrication can boost your refinery’s overall productivity and profitability.

5. High Purity Standards:

Polypropylene’s inert properties ensure that it does not introduce impurities into the refining process, maintaining the purity of the precious metals being processed.

This is crucial for achieving the highest quality products and maximizing the market value of your refined metals.

The contamination-free environment provided by polypropylene systems guarantees the purity of your output, which is critical in the competitive precious metal market.

6. Cost-Effectiveness:

Polypropylene’s long lifespan and minimal maintenance needs make it an extremely cost-effective solution. The initial investment in polypropylene equipment is often offset by the significant savings in maintenance, repairs, and downtime.

Over time, refineries can expect to see a substantial return on investment, with reduced operational costs and increased profitability.

7. Customization:

We understand that each refinery has its own unique requirements, which is why we offer highly customizable solutions. Whether you need a specific size tank, custom piping, or specialized components, we can design and fabricate equipment that perfectly fits your needs.

Our team works closely with you to ensure that every solution is tailored to your refinery’s specific processes and operational requirements.

8. Lightweight and Easy to Install:

Polypropylene is significantly lighter than traditional materials like steel or concrete, making installation easier and faster. This reduces the labor required for setup and minimizes the risk of damage during transportation and handling.

Additionally, the lightweight nature of polypropylene reduces the strain on your refinery’s infrastructure, making it easier to implement upgrades or move equipment when necessary.

9. Thermal Stability:

Polypropylene retains its strength and performance even under moderate heat, making it suitable for high-temperature processes common in precious metal refining.

Its thermal stability ensures that it can perform reliably in challenging conditions, maintaining optimal functionality even in extreme environments.

Why Choose Us?

1. Industry Expertise:

With years of experience in the precious metal refining industry, our team possesses deep knowledge of the challenges faced by refineries and the solutions required to overcome them.

Our engineers and fabricators have the expertise to design and deliver custom solutions that address your specific needs, ensuring the success of your refinery operations.

2. Uncompromising Quality:

We pride ourselves on delivering only the highest-quality polypropylene materials and products. Every piece of equipment we manufacture undergoes rigorous testing and quality control procedures to ensure it meets the highest standards of durability, performance, and safety.

3. Innovation:

We are committed to continuous improvement and innovation. Our team stays at the forefront of polypropylene fabrication technology, incorporating the latest advancements to provide cutting-edge solutions that enhance the efficiency, safety, and profitability of your refinery.

4. Client-Centric Approach:

We believe in building long-term partnerships with our clients. We take the time to understand the unique needs and challenges of your refinery, offering personalized solutions that are designed to meet your specific goals.

Our customer-first approach ensures that we exceed expectations and deliver value at every stage of the process.

Act Now:

Invest in the future of your precious metal refinery with our advanced polypropylene fabrication solutions.

Contact us today for a consultation and discover how we can help you enhance safety, improve efficiency, and maximize profitability. Let us partner with you to refine your operations and position your refinery for long-term success.