Advanced Effluent Treatment Plant for Precious Metal Refineries: Maximizing Recovery, Minimizing Environmental Impact

The Challenge Facing Precious Metal Refineries

Precious metal refineries play a crucial role in the global economy by processing valuable metals such as gold, silver, platinum, and palladium. However, the refining process generates wastewater that is often laden with toxic heavy metals, acids, and chemicals used in extraction processes.

The challenge for refineries is managing this wastewater while ensuring compliance with stringent environmental regulations, minimizing precious metal loss, and controlling costs associated with waste disposal. Unfortunately, many existing effluent treatment systems fall short in meeting these requirements.

The primary challenges faced by precious metal refineries in wastewater management include:

- Loss of Precious Metals: The wastewater generated during refining often contains valuable precious metals. If these metals are not effectively recovered, refineries lose out on a significant source of revenue. Traditional treatment processes frequently fail to capture these metals, leading to a direct loss in profit.

- Inconsistent Effluent Quality: Effluent from a refinery can vary greatly in composition due to fluctuating chemical processes, pH levels, and metal concentrations. Maintaining consistent effluent quality is crucial for meeting regulatory discharge standards. Without a reliable treatment system, refineries face the risk of regulatory non-compliance and potential fines.

- Excessive Sludge Generation: Wastewater treatment processes, particularly those relying on chemical coagulants, often result in the generation of large volumes of sludge. Not only does this increase disposal costs, but improper sludge management can also lead to environmental contamination, affecting nearby water sources and ecosystems.

- Difficulty in Meeting Stringent Environmental Regulations: Regulatory frameworks around wastewater discharge are becoming increasingly stringent, requiring refineries to meet specific limits for pollutants such as Biological Oxygen Demand (BOD), Chemical Oxygen Demand (COD), suspended solids, and heavy metals. Failing to meet these standards can result in heavy fines, shutdowns, or damage to a refinery’s reputation.

Our Solution: Tailored Effluent Treatment for Precious Metal Refining

To address these challenges, we offer a highly specialized and integrated effluent treatment plant designed specifically for precious metal refineries. Our solution combines advanced technology, engineering expertise, and custom design to provide an effective, scalable, and environmentally sustainable solution to wastewater management. With our effluent treatment system, refineries can expect:

- Maximized Precious Metal Recovery: Our plant uses advanced filtration and precipitation methods to recover the precious metals found in the wastewater. This helps refineries recapture valuable metals that would otherwise be lost, increasing profitability and reducing material waste.

- Consistent Effluent Quality and Compliance: With automated pH control and chemical dosing systems, our treatment plant ensures consistent effluent quality. The system also adheres to strict regulatory guidelines, helping refineries maintain compliance with both local and international environmental standards.

- Reduced Sludge Volume and Disposal Costs: Our optimized coagulation and flocculation processes significantly reduce the volume of sludge generated. This not only lowers disposal costs but also minimizes the environmental impact of waste management. By decreasing the need for costly sludge disposal methods, refineries can reduce operational costs.

- Effective BOD and COD Reduction: Our advanced aeration and filtration systems excel at reducing both BOD and COD levels in wastewater, ensuring that the effluent meets or exceeds environmental discharge standards. This helps refineries maintain their environmental licenses and avoids potential penalties from regulatory authorities.

- Scalability and Customization: Every refinery is different, and our treatment systems are designed to be modular and scalable to meet the unique needs of any refinery, regardless of size. Whether you’re a small-scale operation or a large, high-capacity refinery, we can tailor our solution to suit your specific requirements.

- Durable and Reliable Performance: Built with high-quality materials, our effluent treatment systems are designed for longevity and minimal maintenance. Our robust construction ensures the plant can handle the demanding nature of precious metal refining operations while providing reliable performance over the long term.

- User-Friendly Operation with Automation: Our system is equipped with advanced automation and intuitive controls, reducing the need for manual intervention and ensuring ease of operation. Automated processes minimize human error, reduce labor costs, and allow operators to focus on other critical tasks.

- Full Regulatory Compliance: Our treatment system is designed to meet all local and international environmental regulations, including those set by Pollution Control Boards. Refineries using our system can be confident that their operations will comply with current and future regulatory requirements.

Key Features & Benefits

The effluent treatment plant we provide is equipped with the latest technology and features that ensure optimal performance, cost-efficiency, and environmental responsibility:

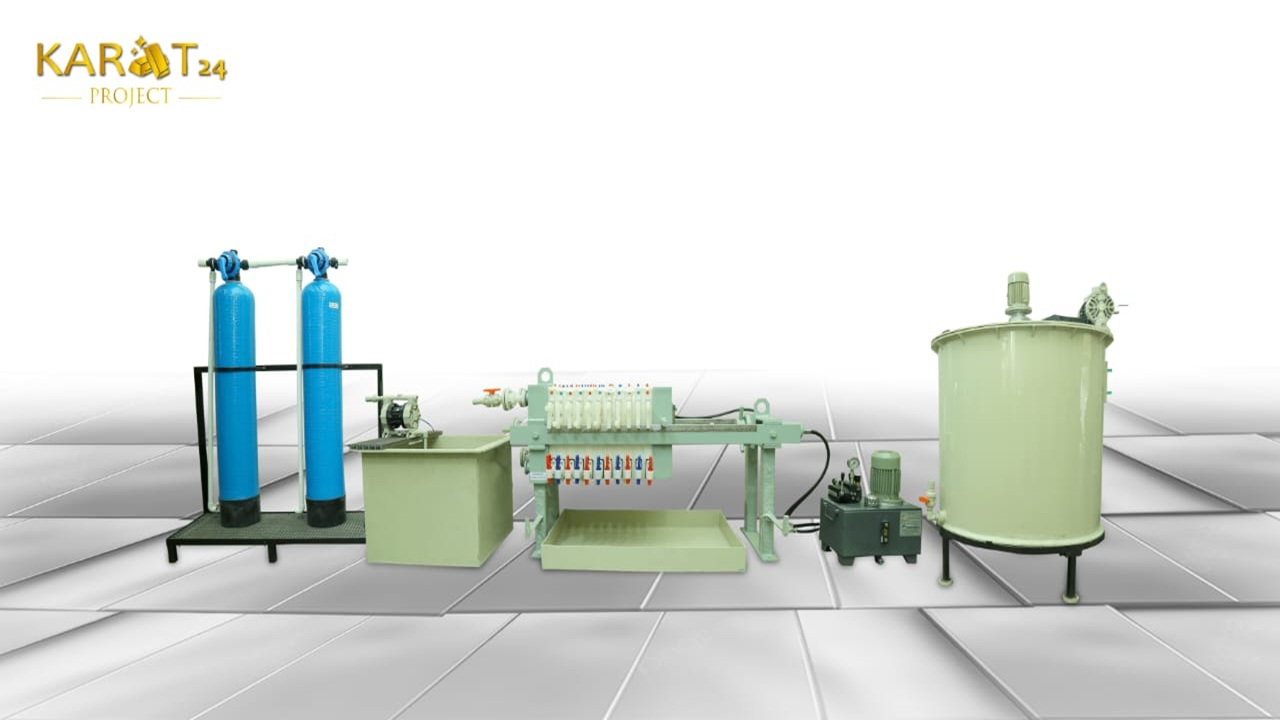

- Collection Tank with Automated pH Control:

- The collection tank ensures stable influent conditions by automatically adjusting the pH levels, which helps maintain the consistency of the wastewater before treatment. This step is essential for effective chemical treatment and optimizing recovery rates.

- Chemical Dosing System:

- Our chemical dosing system precisely controls the addition of treatment chemicals, ensuring that the right amounts are added at the right times. This system maximizes the efficiency of the treatment process while minimizing the consumption of chemicals, leading to cost savings.

- Settling Tank:

- The settling tank effectively removes suspended solids, including precious metals, by allowing them to precipitate and settle. This is a critical step in recovering valuable metals and ensuring that the effluent is as clean as possible before further treatment.

- High-Efficiency Filter Press:

- After precipitation, the filter press dewaters the sludge, reducing its volume and preparing it for disposal. This is an important feature for refineries looking to minimize sludge disposal costs and environmental impact.

- Aeration Tank with Turbine Blower:

- The aeration tank is designed to reduce BOD and COD levels in the wastewater. By using a turbine blower to introduce oxygen into the tank, our system accelerates the breakdown of organic compounds, ensuring high-quality effluent that meets discharge standards.

- Activated Carbon and Sand Filters:

- After the primary treatment, activated carbon and sand filters are used to polish the effluent, removing any remaining contaminants and ensuring that the final effluent meets the highest standards for discharge.

The Advantages of Choosing Our Solution

When you choose our specialized effluent treatment plant, you gain access to a wide range of benefits that go beyond just meeting regulatory requirements:

- Specialized Expertise: We understand the unique challenges of precious metal refinery wastewater management, and our systems are designed specifically to address these challenges. Our team’s deep industry knowledge ensures that our solutions are optimized for maximum efficiency and effectiveness.

- Custom-Tailored Systems: No two refineries are the same, which is why we offer fully customizable treatment systems. Our engineers work closely with each client to design a system that fits the specific needs of their operation, ensuring optimal performance and cost-effectiveness.

- Proven, Advanced Technology: We utilize only the most reliable and proven treatment technologies, ensuring that each system delivers the highest recovery rates and environmental performance. Our advanced processes are built on years of industry experience and research.

- Comprehensive Support and Services: From initial consultation and system design to installation, operation training, and ongoing technical support, we offer a full range of services to ensure the success of your wastewater treatment plant. Our support team is always available to assist with any operational challenges.

- Environmental Sustainability: Our system is not only designed to meet regulatory requirements but also to minimize the environmental footprint of your operations. Reduced sludge production, efficient metal recovery, and optimized chemical use all contribute to a more sustainable refinery operation.

- Cost-Effective Operations: By maximizing metal recovery, reducing chemical use, minimizing sludge production, and lowering maintenance costs, our effluent treatment solution helps refineries reduce operating expenses while maintaining regulatory compliance.

Invest in Sustainable and Efficient Wastewater Management

As the demand for precious metals continues to grow, the need for efficient, cost-effective, and environmentally responsible wastewater treatment becomes more critical. Our specialized effluent treatment plant offers refineries the opportunity to maximize metal recovery, minimize environmental impact, and ensure compliance with the toughest regulations.

By choosing our solution, you are investing in a future of sustainable, profitable, and compliant operations. Let us help you achieve operational excellence, reduce costs, and contribute to a cleaner environment while recovering more valuable precious metals from your wastewater.

Contact us today to learn how we can help optimize your precious metal refinery’s wastewater management system.